Hello again! I’m taking a quick break from upgrading and tweaking my printer to actually use it for once. This time for something quite useful! Recently, our family sold our home and are in the process of building a new one. Well not ourselves… I mean if I did I would just print it. Anyway, this means that we are currently living with our parents and adapting to a new environment. Well, new environment comes with new challenges, like how the hell am I supposed to setup a baby monitor without putting holes in the walls. Well, that’s where some 3D printing comes in 🙂 Lets get into it!

Why buy when you can print!

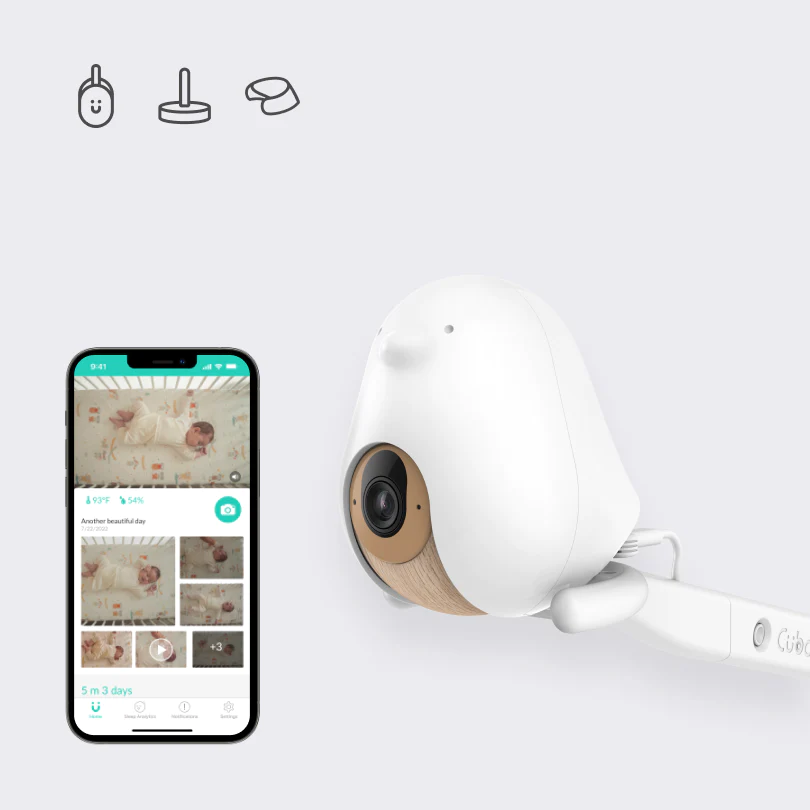

The Cubo AI baby monitoring system. A night vision camera with some sweet AI tech to tell you when the baby cries, coughs or rolls over onto their face. Packed with a night light, temp/humidity sensor and streams everything to the cloud for maximum availability and accessibility. Even has a speaker built in to play gentle chirping or lullaby music. You can even talk through the mic to tell your kid to shut up and go to sleep while you are trying to enjoy a nice night out.

While the tech is amazing, its practicality and portability is kind of lacking… The standard camera comes with a nice wall mounting kit, to help keep it out of reach and centered over the crib. Works really well! Until you move someplace where you can’t put holes in the walls. No worries, just plop that sucker on the shelf right next to the crib! Oh right, its egg shaped so it just rolls off if someone sneezes in the room…

Well its a good thing that the company thought of this already and crafted a table top accessory for this very situation. I’ll just crunch in my credit car…. $30?! For a small piece of plastic?!

Yeah, I’m not about that. I won’t even pay the small fee to make my IP address for this site static! The good thing is, since I can’t do much while this house sells, I’ve gotten pretty proficient in Blender and Fusion 360 doing 3D modeling. Lets go cook this thing up!

Throwing the Camera in the Blender

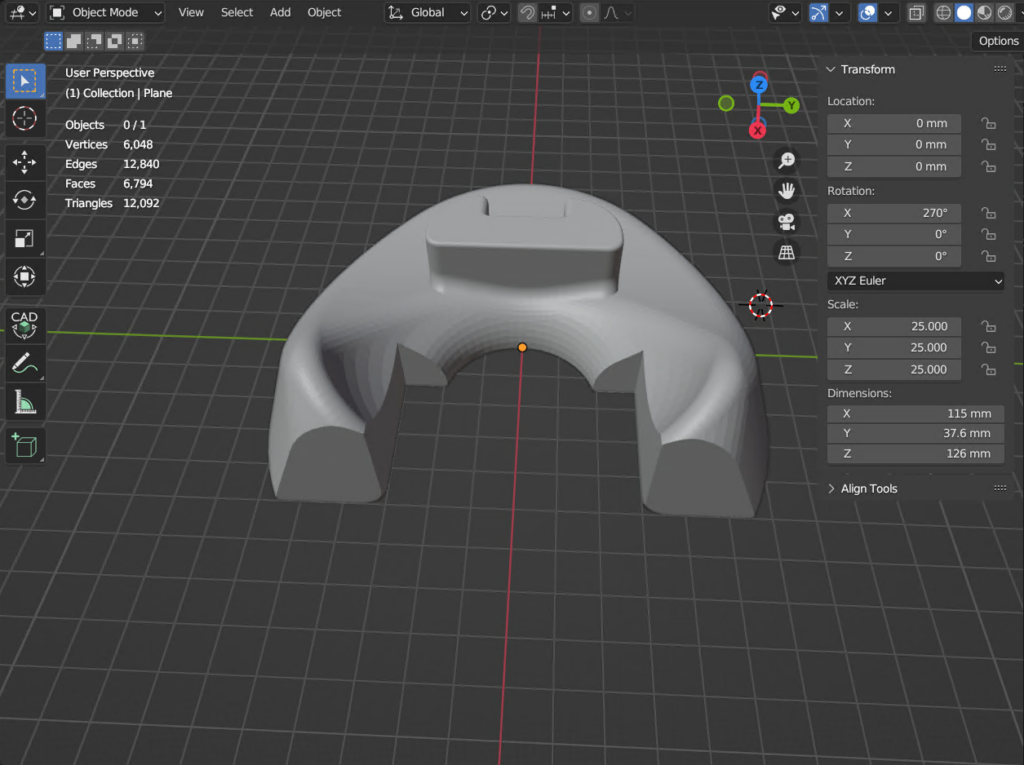

From the website I was able to pull the camera dimensions and guess the rest of the angles and curves. One nice perk of living with my in-laws is my father-in-law is a mechanical engineer and a wizard at using Solid Works. He took interest at my project and before I had a chance to fire up blender he already had a STL for me.

Hey, I’ll take it! I’d rather have a seasoned veteran do it right vs whatever I can slap together. The first iteration wasn’t a 100% success. The “legs” of the mount were really thick and were in view of the camera lens. When night vision kicks in, its like a flash light, flooding the room with IR light. Those legs would then reflect the IR light back into the lens, making the room foggy.

To fix this, I hopped into Blender to add my own mods. Basically taking a nice big square chunk out of the legs so they did not appear in view. And voilà! Problem solved!

But again, my father-in-law couldn’t help himself and improve upon my design, smoothing everything out and making it much more professional looking. Behold the final results, printed in white to match!

I can now sleep soundly knowing that my printer and all its upgrades saved me $30. Being that an entire spool of PLA is $20, that’s a hell of return on investment 🙂

The Power of 3D printing!

This post much like making the diaper pail handle or the blind cord winders, I’m understanding that this is the future of micro manufacturing or at least minimizing the disposable culture. Lost that cap to your favorite bottle? No need to buy a whole new one! Broke a bracket on your favorite shelf, no problem! I just need to build my CAD skills, then I will be unstoppable!!

But until then, I’ll just keep settling on finding things on Thingiverse or reaching out to then many smart engineers I know 🙂

That’s all for this one, see you again soon!